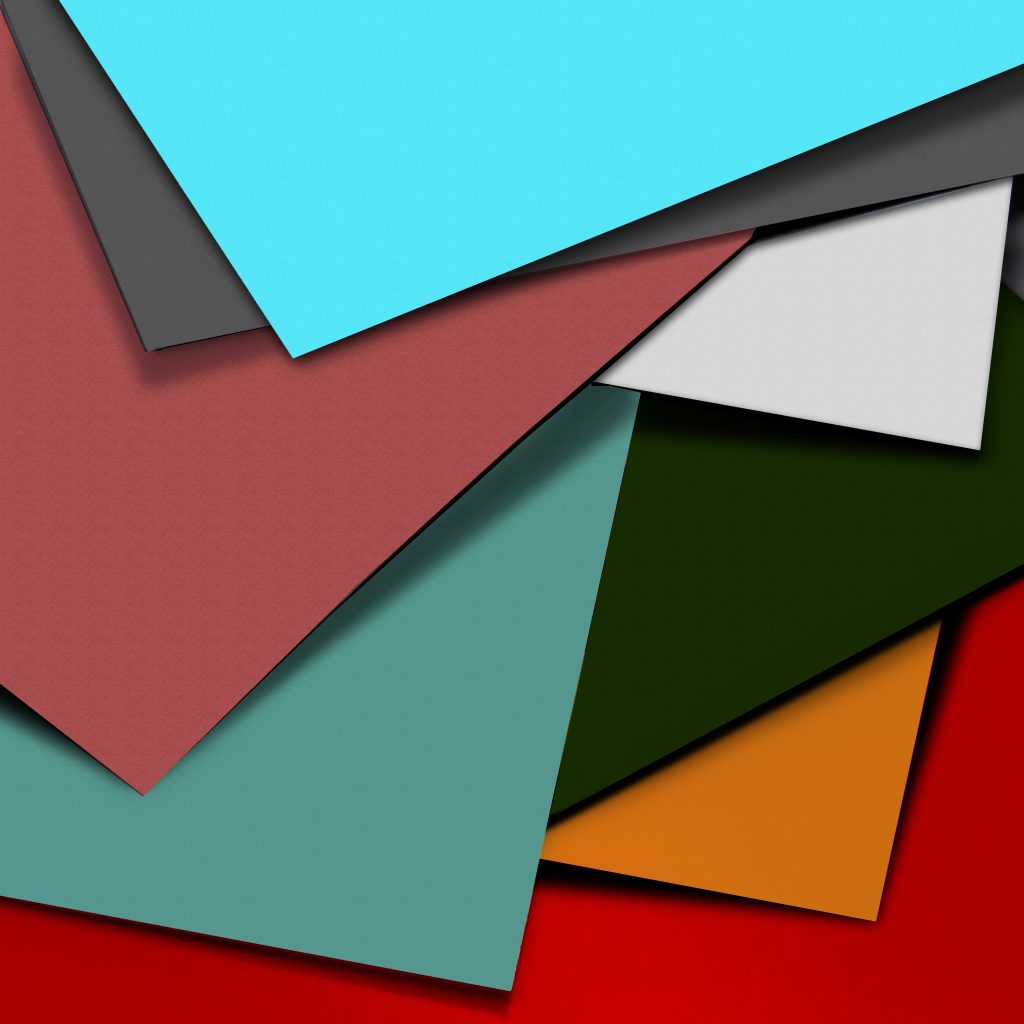

HIGH PRESSURE LAMINATE

HPL | CPL

CPL is Continuous Pressure Laminates.

HPL is High Pressure Laminate.  HPL is regarded superior to CPL.

HPL is regarded superior to CPL.

HPL thickness generally ranges from 0.5-1.5mm.

Decorative Laminate and Compact Laminate outperform all traditional decorative surfaces known in the industry and are suitable for almost all interior applications, such as but not limited to:

– Paneling & Cladding.

– Doors & Wardrobes.

– Furniture & Tabletops.

– Counter & Kitchen Tops.

– Vanity Cabinets.

– Lockers & bathroom Cubicles.

– Store Display Units.

HPL & Compact Laminate are extremely durable and are considered the best decorative surfaces for high traffic areas such as airports , restaurants and public buildings decorative wall cladding and various furniture items. Compact laminate is the obvious ,most convenient , most economical space-saving, water-proof and anti-vandalism decorative board for bathroom cubicles and wet area lockers.

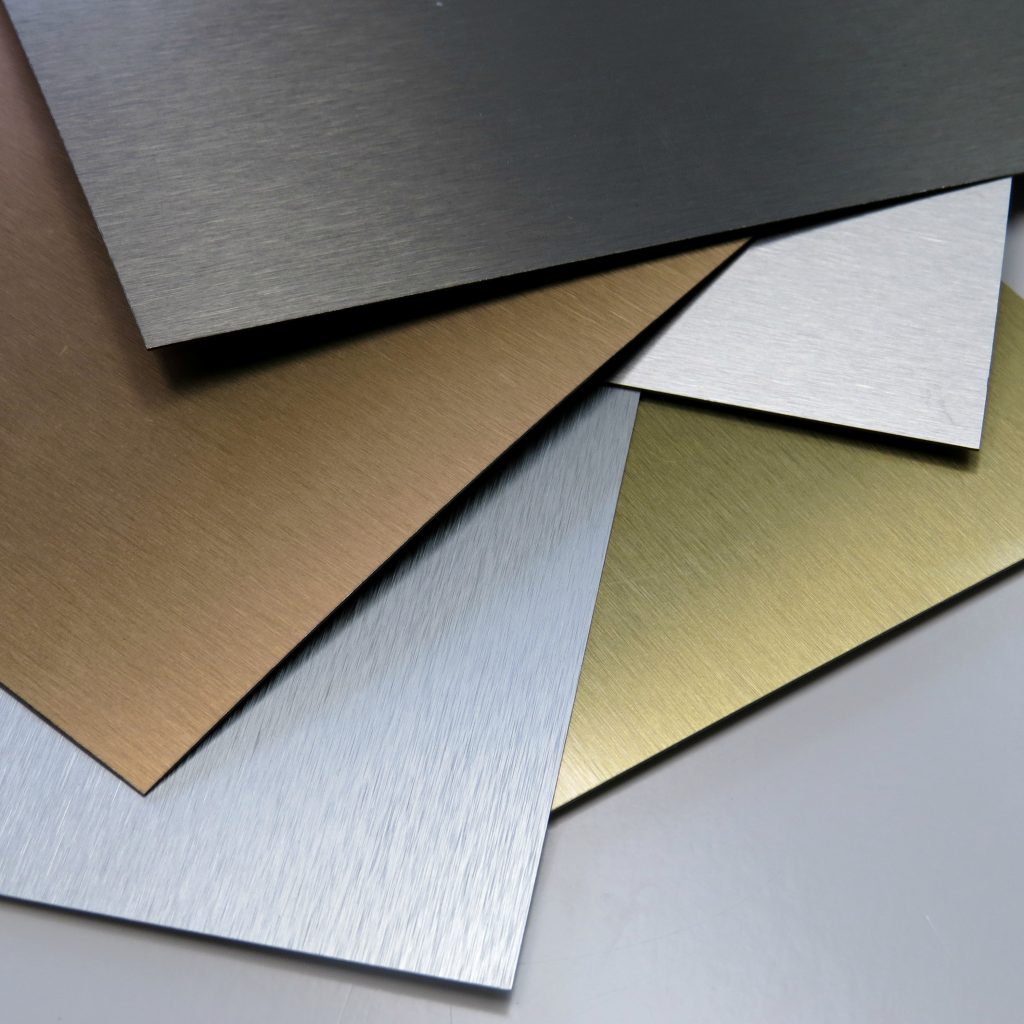

Décor Paper:

Laminate face is decorative printed paper in various designs, solid color, wood grain, mineral, fabric, leather….etc. The quality of décor paper is generally differentiated by the quality of print and the grammage of paper which normally ranges from 60 to 130 g/m2.

Kraft Paper:

HPL body is comprised of phenolic resin impregnated papers called Kraft paper. They generally range in weight from 80 to 300 g/m².

Underlay:

A layer of paper that separates décor paper from kraft paper. It may not be always used.

Overlay:

Transparent paper pressed on top of décor paper to improve scratch resistance and protection of printed design/color.

Classification

Alphabetically:

In EN 438-3: ,three letters are used to classify a laminate:

1st letter : H for Horizontal application or V for Vertical application.

2nd letter : G for general purpose or D for Heavy-Duty.

3rd letter: S for Standard quality, P for Post forming grade or F for Flame retardant.

Numerically:

A numerical system is also defined in relation to the three important characteristics:

Abrasion resistance : overlay related.

Impact resistance : laminate thickness related.

Scratch resistance: texture type related.

Would you like to discuss a project?

TEXT

© Copyright Lamex Laminate 2019